Understanding the Secret Components and Repair Service Strategies for Packaging Device Maintenance

Effective maintenance of product packaging devices pivots on an extensive understanding of their vital elements, consisting of the framework, drive system, and securing devices. Identifying typical maintenance concerns, paired with the application of preventative strategies and fixing strategies, can considerably improve machine dependability. Furthermore, the option of repair service techniques, including the use of OEM components and the significance of licensed service technicians, plays an essential duty in reducing downtime. To genuinely comprehend the complexities of these systems and their upkeep, one must consider the more comprehensive effects of neglecting these important practices.

Trick Elements of Product Packaging Makers

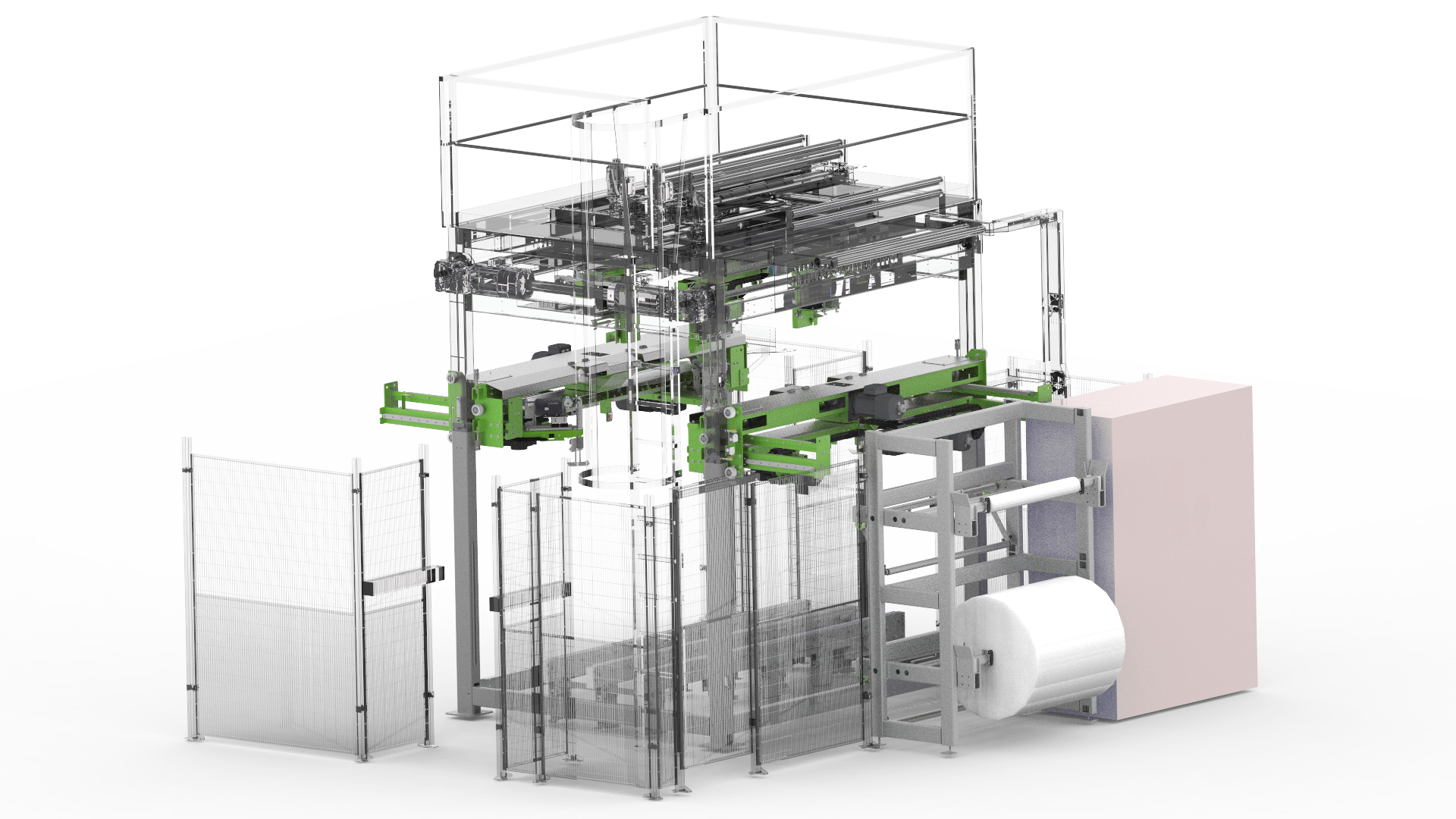

Packaging devices include several key parts that interact to guarantee efficient and effective packaging processes. At the core of these machines is the frame, which gives architectural stability and houses the various operating components. The drive system, commonly a mix of equipments and motors, facilitates the activity of elements, allowing precise procedure throughout the packaging cycle.

Another crucial element is the conveyor system, which moves products via different phases of the product packaging process. This is usually enhanced by sensors and controls that check the setting and speed of things, guaranteeing synchronization and minimizing mistakes. The filling up system is crucial for properly dispensing the appropriate quantity of item into plans, whether in fluid, powder, or strong form.

Securing mechanisms, consisting of warmth sealers or sticky applicators, play a crucial duty in safeguarding packages, protecting against contamination and prolonging rack life. Additionally, classifying systems are essential for giving required item information, making sure conformity with guidelines. Ultimately, the control board, equipped with easy to use user interfaces, allows drivers to take care of device features, display performance, and make changes as needed, making certain optimum productivity and effectiveness in product packaging procedures.

Typical Upkeep Concerns

Reliable procedure of packaging machines depends heavily on routine upkeep to stop common concerns that can disrupt production. Among these issues, mechanical wear and tear is common, especially in elements like conveyors, electric motors, and seals, which can bring about unanticipated downtimes. In addition, misalignment of components can cause ineffective operation, causing items to be improperly packaged or harmed during the process.

One more common maintenance concern entails the buildup of dirt and particles, which can hinder the device's sensing units and moving components. packaging machine repair service. This not just affects performance yet can additionally pose safety and security threats. In addition, lubrication failures can bring about boosted rubbing, leading to getting too hot and eventual part failure.

Electrical problems, often originating from loose links or damaged electrical wiring, can interrupt equipment features, bring about considerable production hold-ups. Software program glitches due to obsolete programs or incorrect configurations can impede the machine's procedure, requiring prompt intervention. Addressing these typical upkeep problems proactively is essential for making sure optimal efficiency and durability of product packaging machinery.

Preventative Maintenance Strategies

Carrying out preventative maintenance methods is crucial for maintaining the performance and dependability of product packaging machines. These methods encompass a methodical strategy to maintenance, concentrating on the regular evaluation and maintenance of equipment to preempt prospective look at these guys failings. By adhering to a scheduled upkeep program, drivers can identify deterioration on parts before they bring about considerable malfunctions.

Crucial element of a preventative upkeep strategy include routine examinations, part, cleansing, and lubrication replacements based upon producer referrals. Utilizing checklists can simplify this process, making certain that no important jobs are ignored. In addition, keeping accurate records of maintenance activities help in tracking the machine's efficiency in time, facilitating notified decision-making relating to future upkeep requirements.

Educating personnel on the value of preventative upkeep improves compliance and promotes a society of aggressive treatment. Applying an anticipating upkeep part, making use of information analytics and sensing unit innovation, can additionally optimize equipment efficiency by anticipating failings before they happen.

Fixing Methods

When faced with malfunctions or inefficiencies in packaging equipments, using organized troubleshooting methods is vital for determining and fixing issues swiftly. The primary step in reliable troubleshooting is to develop a clear understanding of the equipment's functional specifications and performance metrics. This entails examining the maker's specifications, as well as any kind of error codes or notifies presented.

Next, operators need to carry out a visual examination, looking for apparent signs of damages, misalignment, or wear. This often consists of checking out sensing units, belts, and equipments to pinpoint possible sources of malfunction. Collecting operational information, such as production prices and downtime logs, can likewise offer insights into reoccuring issues.

When possible problems are recognized, using a sensible approach to separate the origin reason is essential. This may call for basics testing specific components or systems in a regulated way. Engaging in conversations with operators who connect with the equipment consistently can produce important responses regarding unusual habits or patterns.

Repair Work and Replacement Best Practices

A comprehensive understanding of fixing and substitute finest practices is crucial for preserving the durability and efficiency of product packaging makers. Regularly evaluating the condition of maker parts enables timely intervention, avoiding more considerable concerns that can bring about pricey downtimes.

When repair services are essential, it is important to use OEM (Original Devices Maker) components to make certain compatibility and efficiency. This not just maintains the integrity of the machine but also upholds warranty agreements. Additionally, it is advisable to keep a supply of essential extra components to assist in quick replacements and minimize operational disruptions.

For complex repairs, engaging qualified professionals with specialized training in product packaging equipment is suggested. They have the expertise to detect issues accurately and carry out repair services effectively. Furthermore, recording all fixing tasks and parts replacements is crucial for preserving a thorough upkeep history, which can aid in future troubleshooting.

Finally, implementing an aggressive technique, including normal assessments and predictive upkeep methods, enhances the reliability of product packaging makers. By adhering to these ideal methods, businesses can make sure optimal equipment performance, lower operational threats, and prolong equipment life-span.

Conclusion

In final thought, a complete understanding of product packaging equipment parts and effective maintenance techniques is crucial for optimum performance. By executing these practices, organizations can make sure the long life and performance of product packaging equipments, inevitably adding to improved operational efficiency and minimized expenses (packaging machine repair service).

Efficient upkeep of packaging devices hinges on an extensive understanding of their crucial parts, consisting of the framework, drive system, and sealing mechanisms.Reliable procedure of packaging machines relies greatly on routine maintenance to prevent typical problems that can disrupt production.Implementing preventative upkeep approaches is important for maintaining the address efficiency and reliability of product packaging makers. Additionally, maintaining exact records of upkeep tasks help in tracking the machine's efficiency over time, promoting notified decision-making regarding future upkeep requirements.

Comments on “Packaging Machine Repair Service: Rapid and Economical Solutions for Your Service”